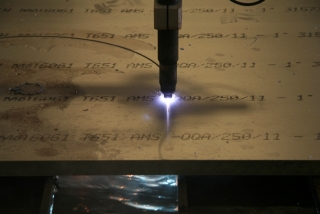

CNC Plasma Cutting

Plasma cutting is process used to cut steel and other metals using a plasma torch. In this process, and inert gas is blown at high speed out of a nozzle, at the same time and electrical arc is formed through that gas from the nozzle to the surface being cut, turning some of that gas to plasma. The plasma is sufficiently hot to melt the metal being cut and moves sufficiently fast to blow molten metal away from the cut.

Turntec has the ability to take our engineered drawings and convert them over to a plasma software. The drawing is then prepared, nested and directly transformed into a cutting-required file. We offer in house and state of the art equipment that easily handles metal and steel fabrication. Once the file is loaded

Our CNC Plasma Cutting Capabilities:

Cutting Range:

– X Axis : 1200 mm(47″)

– Y Axis :2000 mm( 78″)

Cutting Thickness:

6-150mm(0.2″-5.9″ )

Contact TurnTec for your CNC plasma cutting needs.